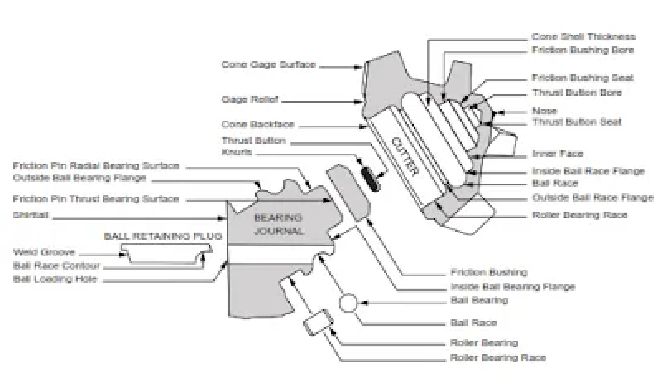

Izinhlobo ezahlukahlukene zamabhithi e-Rock kanye nohlelo lokuthambisa lwe-Roller Cone Drill Bits olusetshenziselwa ukuvikela amabhere.Isistimu yakudala ehlanganisa ukusebenzisa uketshezi lokumba njengezithambisi, kuyilapho amasistimu akamuva asebenzisa amagrisi ukuthambisa.Uketshezi lokumba oluqukethe izinto eziqinile ezilumayo ukuze zibe isici esikhawulelwe ngokuhlobene nokugijima kwebhithi okude futhi akuvamile ukuthi zisetshenziswe njengezithambisi kumabhithi anamuhla.Isibonelo amakhoni we-tricone bits, i-roller cone drill bit ifakwe kumajenali njengoba kukhonjisiwe kumklamo ongezansi.

Izingcezu zokubhoboza, izingcezu ze-Tricone ze-Rock Roller Cone Drill Bit Bearing Design

Izinhlobo Ezintathu Ezivamile Zokwakhiwa Kwe-Bearings Ezisetshenziswa Kulawa mabhithi e-tricone rock Roller Cone Drill Bits:

1.Isistimu yamabhithi e-roller, akha umhlangano wangaphandle ukusekela ukulayisha kwe-radial (noma i-WOB)

2.Isistimu ye-Ball Bearings, emelana nemithwalo ye-longitudinal noma i-thrust futhi isiza nokuvikela ama-cones kumajenali.

I-3.I-Friction Bearing System, ekuhlanganiseni kwekhala esiza ukusekela ukulayishwa kwe-radial.I-friction bearing iqukethe isihlahla esikhethekile esicindezelwe ekhaleni le-cone.Lokhu kuhlanganiswa nephinikhodi yokuhlola kujenali ukukhiqiza i-coefficient ephansi yokungqubuzana ukuze imelane nokubanjwa nokuguga.

Zonke izinto ezithwalayo kufanele zenziwe ngensimbi eqinile enokumelana okuphezulu nokuqhekeka nokuqhekeka ngaphansi komthwalo onzima okufanele bakusekele.Njengazo zonke izingxenye ze-roller cone drill bits, ukwelashwa kokushisa okusetshenziselwa ukuqinisa insimbi.

Izici ezibaluleke kakhulu zokuklama komhlangano wama-bearings ukutholakala kwesikhala.Ngokufanelekile ukuthwala kufanele kube kukhulu ngokwanele ukusekela ukulayisha okusetshenzisiwe, kodwa lokhu kufanele kulinganiswe namandla ejenali kanye negobolondo lekhoni okungaba umsebenzi wobubanzi bejenali kanye nogqinsi lwegobolondo lekhoni.

Idizayini yokugcina iwukuvumelana okuqinisekisa ukuthi, ngokufanelekile, ama-drill bits bearings ngeke aguge ngaphambi kwesakhiwo sokusika (zonke izingcezu ze-tricone, ama-rock bits, izingxenye ze-roller drill drill kufanele ziguge ngokulinganayo).Kodwa-ke, ukulayishwa komjikelezo obekwe kuma-bearings kuzo zonke izimo, ekugcineni kuqalise ukwehluleka.Uma lokhu kwenzeka ibhalansi nokuqondanisa komhlangano kuyachithwa futhi ama-cones akhiyelwe kumajenali.

Isikhathi sokuthumela: Jan-13-2023