UMFANEKISO WE

IKHODI YE-IADC YE-TRICONE BITS

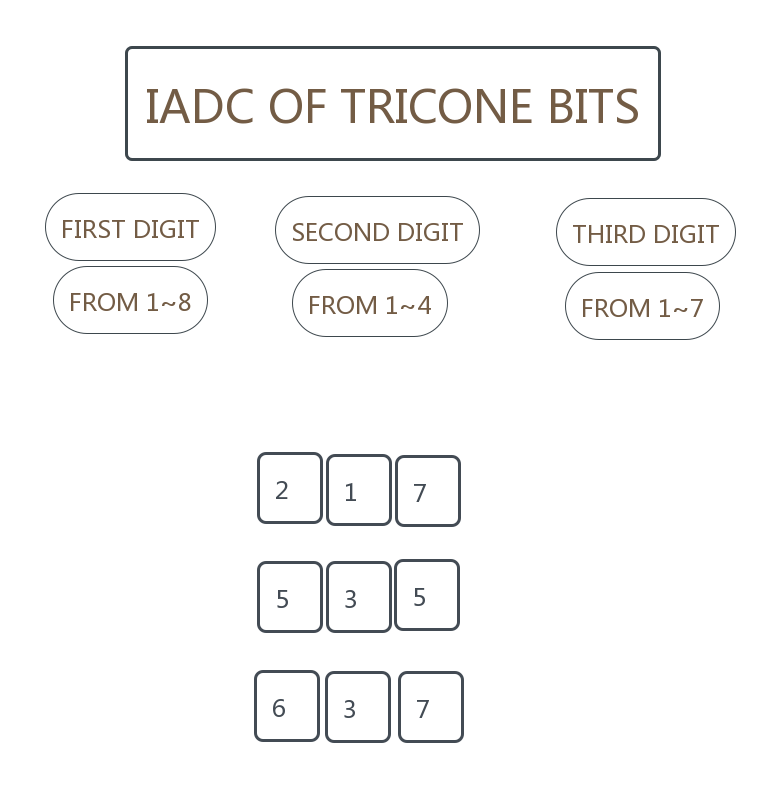

I-IADC-AMADIGIDI AMATHATHU

| IDIGIDI LOKUQALA | IDIGIDI LESIBILI | IDIDITHI YESITHATHU | ||||

| KUSUKA 1~8 Inombolo ephezulu isho ukwandisa inani lamazinyo ukuze kube nzima ukwakheka | KUSUKA 1~4 | KUSUKA 1~7 Le dijithi ihlukanisa amabhithi ngokuya ngohlobo lwe-bearing/seal kanye nokuvikela okukhethekile kwegeji njengozakwethu | ||||

| 1

| IZINYO ZEZINYO /IZINYO EZIGULIWE | Ukwakheka okuthambile okunamandla acindezelayo aphansi kanye nekhono eliphezulu lokubhola | 1,2,3,4 isiza ngokuqhubekayo ukubhidliza ukwakheka okungaphansi komhlaba kuthi oku-1 kube okuthambile kakhulu futhi okungu-4 kube nzima kakhulu | 1 | I-Bearing evulekile/ I-Non-sealed | Izingcezu zerola ezithwele evulekile ezijwayelekile |

| 2 | IZINYO EZIGIDIWEYO | Ukwakheka okuqinile Okumaphakathi kuya Kumaphakathi okunamandla acindezelayo aphezulu | 2 | Ibhithi elijwayelekile elivulekile lokumba umoya kuphela, izingcezu ze-tricone zokumba kahle. | ||

| 3 | IZINYO EZIGIDIWEYO | Ukwakheka okuqinile kwe-semi-abrasive kanye ne-abrasive | 3 | Ibhithi elivulekile elijwayelekile elinokuvikela kwegeji elichazwa njengokufakwa kwe-carbide esithendeni sekhoni. | ||

| 4 | I-TUNGSTEN CABIDE AYIFAKALE IZIQINISEKISO /TCI BITS | Ukwakheka okuthambile okunamandla acindezelayo aphansi kanye nekhono eliphezulu lokubhola | 4 | Ukufaka uphawu | I-roller evalwe uphawu | |

| 5 | Izindleko zamasheya TCI | Ukwakheka okuthambile kuye kokumaphakathi okunamandla acindezelayo aphansi | 5 | I-roller evaliwe ene-carbide ifaka esithendeni se-cone. | ||

| 6 | Izindleko zamasheya TCI | Ukwakheka okuqinile okumaphakathi namandla acindezelayo aphezulu | 6 | Izingcezu ezinezinhlamvu ezivaliwe zejenali | ||

| 7 | Izindleko zamasheya TCI | Ukwakheka okuqinile kwe-semi-abrasive kanye ne-abrasive | 7 | Ijenali evalwe ngezingcezu ezine-carbide efakwe esithendeni sekhoni. | ||

| 8 | Izindleko zamasheya TCI | Amafomu aqine kakhulu futhi abrasive | ||||

Ikhodi Yezici Zesakhiwo Engeziwe:

Amakhodi ezinhlamvu alandelayo asetshenziswa endaweni enedijithi yesine ukukhombisa izici ezengeziwe:

| Uhlelo lokusebenza lwe-A-Air | B—Special Bearing Seal |

| C-Center nozzle | Isicelo se-M—Motor |

| D—Ukulawula ukuchezuka | E—Indiza Enwetshiwe |

| I-G—Isivikelo segeji eyengeziwe | J—I-Jet Deflection |

| R—Ama-weld aqinisiwe | L—Amaphedi Omlenze |

| S—Izinyo eligaywe elijwayelekile | I-T-Ama-Cone Bits amabili |

| W—Isakhiwo Esithuthukisiwe Sokusika | H—Isicelo Esivundlile |

| X—I-Chisel Insert | I-Y—I-Conical insert |

| Z—Omunye umumo ongenayo |

Isibonelo: 8-1/2” HJT517GL imele?

8 1/2”: Ububanzi bezingcezu zokubhoboza buyi-8.5inch(215.9mm)

I-HJT: Ijenali enensimbi evala uphawu ekhethekile

517: Ukwakheka okuthambile kuya kokumaphakathi okufakwe amandla acindezelayo aphansi

G: Ukuvikelwa kwegeji eyengeziwe

L: Iphedi Lomlenze

Isikhathi sokuthumela: Nov-19-2021